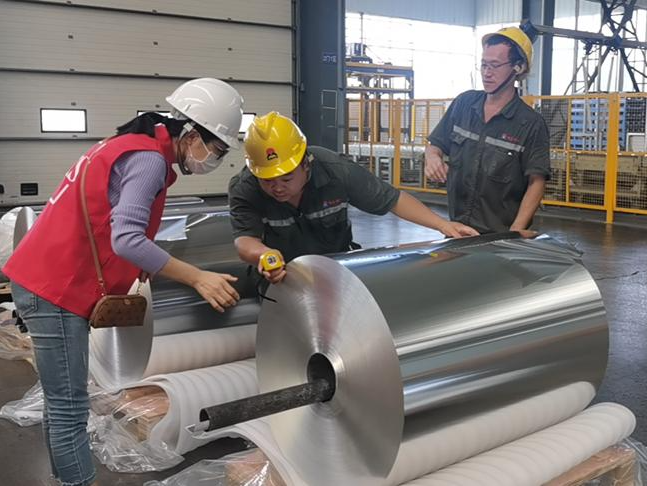

Quality inspection

WE GUARANTEE THE QUALITY OF THE PRODUCT AT ALL STAGES OF PRODUCTION!

The quality inspection consists of performing a random sampling of the order to check the quality of the product. This service is usually carried out at the end of production and can be done at the supplier's plant, at the customer's warehouse or at the Freight Forwarder's yard.

Quality inspection

- A random sampling is carried out in accordance with the ISO 2859 tables, which gives us the number of products to be inspected and the number of defective parts to reject the lot. In the event that the product does not meet the agreed specifications or has defects, it is corrective actions will be taken within the production process. This service allows us to take corrective action at origin and not at final destination. Quality defects are cataloged and the implementation of corrective actions is supervised with the supplier to prevent them from happening again. The balance of the purchase order may be subject to a final quality inspection, thus shielding the operation.